Dual-axis sub-millidegree inclinometer system with ±0.002 Degree resolution

- Rotem Segev

- Nov 4, 2025

- 2 min read

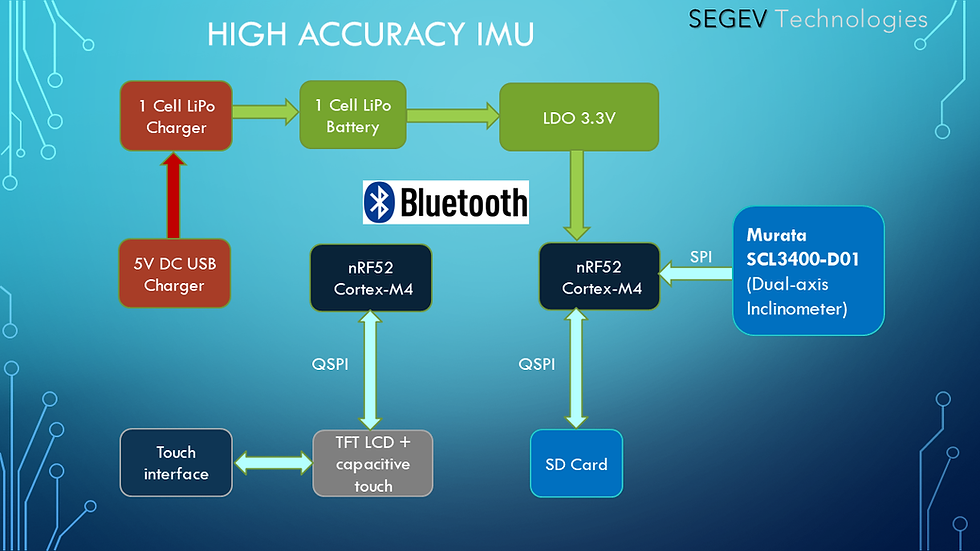

Segev Technologies built an industrial two-node inclinometer solution around Murata’s SCL3400-D01 (2-axis, digital SPI) to level a high-precision wafer stage at a major semiconductor manufacturer. A local sensor head (nRF52 Cortex-M4) acquires tilt data directly from the Murata SCL3400-D01, performs on-board filtering and temperature/cross-axis compensation, and transmits the processed angles over its integrated 2.4 GHz BLE link to a remote display/controller (nRF52), which manages the front-panel user interface and visualization shown in the photos. The system continuously streams X/Y angles in real time and exposes zero/hold presets for the production techs.

• Effective noise: 0.0008–0.0012° RMS @ 0.3–0.5 Hz BW

• Repeatability: ±0.002° (3σ, 10 min stability)

• Thermal drift (after calibration): ±0.003–0.005°

Sensor configuration. We run Mode A (±30°, 10 Hz LPF) to maximize SNR for small-angle leveling near zero. Raw data (2 kHz ODR) is decimated to 200 Hz, then filtered (cascaded bi-quads) to 0.3–0.5 Hz effective bandwidth; this trades a ~1–3 s settling time for sub-milli-degree noise. The display node applies arctan2-based tilt computation and renders both live and averaged values. (SCL3400: ±30°@10 Hz and ±90°@40 Hz ranges; ODR 2 kHz.)

Mechanical design—what enables 0.002° in the fab

Achieving millidegree-class performance in a live silicon-fab environment required as much mechanical work as electronics:

Monolithic aluminum housing (CNC-machined, thick-wall) for stiffness and thermal time-constant—reduces temperature gradients across the MEMS and the PCB. The bezel recess around the display limits drafts over the LCD aperture.

Datum-plane mounting: the base is ground flat and hard-anodized; three-point screw pattern with torque-controlled M3 fasteners sets a repeatable reference. A laser-etched X/Y frame on the lid matches sensor axes to the stage.

Isolation from micro-vibration: a compliant, low-creep elastomer layer filters high-frequency floor/air-handler harmonics while keeping the 0–1 Hz band (our passband) mechanically coupled.

Cable & RF hygiene: shielded feedthrough and PCB-edge RF can (for the nRF/MCU) prevent EMI from stage drives; ground strategy keeps the MEMS return quiet.

Thermal practices: the battery cavity is thermally decoupled; internal components are laid out to avoid hot-spots under the SCL3400. We also slow the internal air exchange via gasketed seams to minimize convective steps when doors open.

Comments